- Home

- Sustainability Report

- Mitsubishi Materials Group's Initiatives on Material Issues

- Prevention of occupational accidents

Strengthening Response to SCQ Issues

Prevention of Occupational Accidents

Creating a Safe and Healthy Workplace Environment

| Theme of activities | Results of activities during FYE March 2024 | Self- assessment |

Targets/plans for activities from FYE March 2025 onwards |

|---|---|---|---|

|

|

C |

|

|

C |

|

|

|

B |

|

|

|

A |

|

|

|

A |

|

|

|

A |

|

Self-assessment grades A: Target achieved B: Target mostly achieved C: Target not achieved

Basic Approach

In the MMC Group, one element of our Code of Conduct is “We are committed to providing a safe and healthy environment for all our stakeholders.” This is based on the notion that, if we cannot keep our employees and all stakeholders around us safe and healthy, they will not be able to provide stable and happy lives for their families, we will not be able to operate effectively, and we will never be able to keep on expanding as a company.

MMC Group Basic Policy on Safety and Health Management

Established on November 10, 2014

- We will carry out safety and health activities based on full participation from all employees, underpinned by leadership and initiative from the CEO and other managing personnel.

- We will ensure that all employees comply with the Industrial Safety and Health Act and other applicable legislation, manuals and operating procedures, and establish a workplace culture whereby everyone follows the rules and ensures that others do too.

- We will make every effort to create pleasant workplaces that are healthy for both body and mind, for all employees, through activities aimed at creating open workplaces and promoting health.

- We will take preventive measures in accordance with Ministry of Health, Labour and Welfare guidelines on the prevention of work-related traffic accidents and improve road etiquette amongst all employees, in order to eliminate traffic accidents based on our commitment to promoting road safety activities as an example to society as a whole.

And since 2018, among the goals represented by SCQDE enacted as the guideline to decision-making concerning conduct of our work (priority order), we have positioned “S” which represents “Safety and Health”, as the first priority.

Guideline to decision-making concerning conduct of our work (priority order)

| 1 | SSafety & Health |

Safety & Health come first |

|---|---|---|

| 2 | CCompliance & Environment |

Compliance & Environment to ensure fair activities |

| 3 | QQuality |

Quality of products and services provided to our "customers" |

| 4 | DDelivery |

Delivery dates to be met |

| 5 | EEarnings |

Reasonable profit (Obtained based on “customer” trust after satisfying SCQD) |

“SCQDE” shows the order of priority of our business decisions. In providing customers with our products & services, we should thoroughly fulfill SCQ at first and then satisfy D. We believe that we will be able to obtain trust from customers and society by continuously executing SCQD in good faith, and this will produce a reasonable profit.

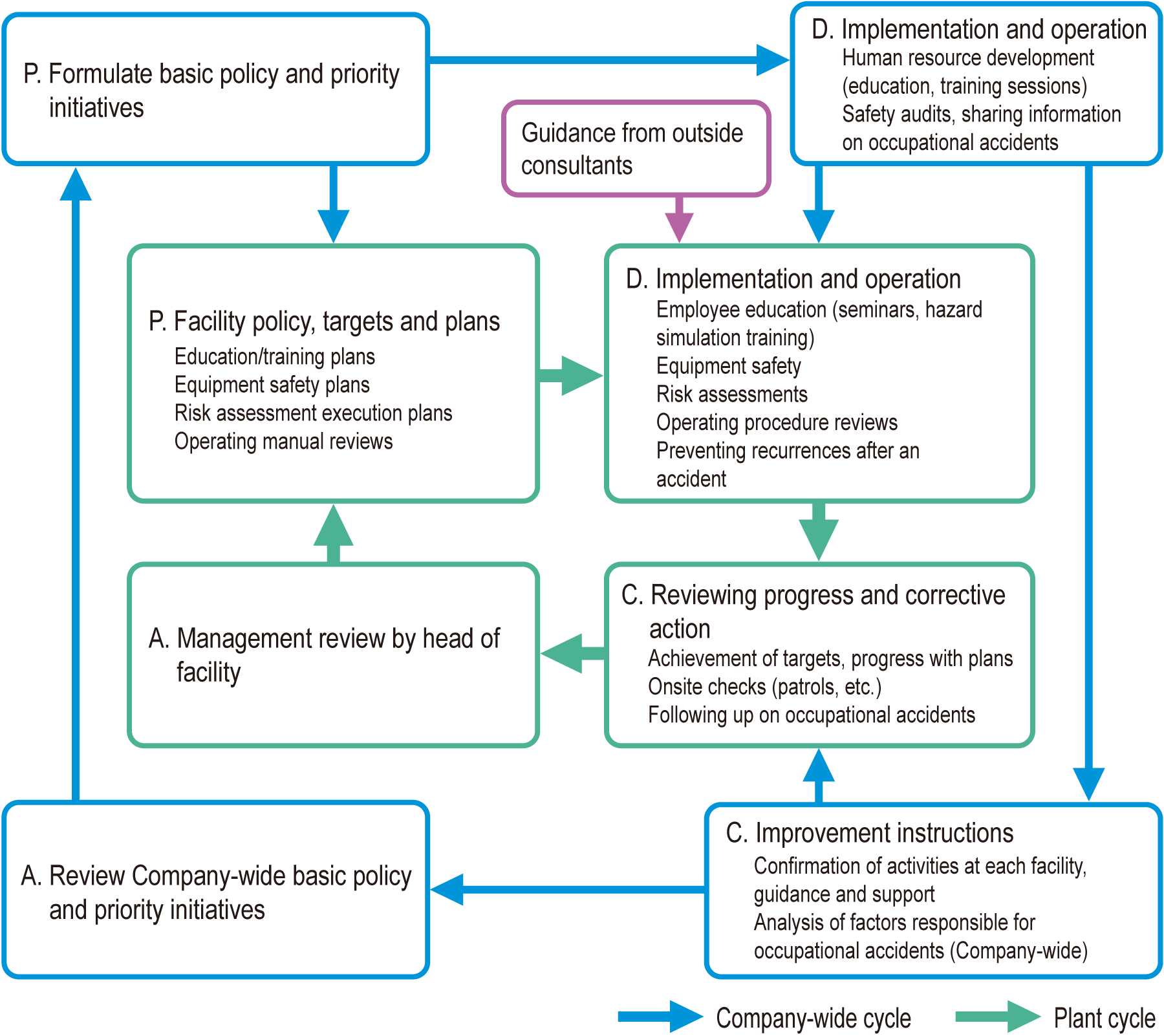

Promotion System

In the wake of the fire and explosion at the Yokkaichi Plant (which was transferred to SUMCO Corporation on March 31, 2023) in January 2014, we launched a Zero Occupational Accident Project in April that same year. Under the Zero Occupational Accident Project, we work to strengthen the foundations of safety and health on a Group-wide scale, with the aim of “not causing any occupational accident resulting in four or more lost days for one year.”

The Zero Occupational Accident Project is led by the Zero Occupational Accident Subcommittee, which serves as a special subcommittee under the SCQ Promotion Office headed by the Chief Executive Officer.

Based on analysis of factors including occupational accidents that have occurred, the Zero Occupational Accident Subcommittee, which consists of Safety Coordinators from the departments, identifies priority issues that our Group should tackle. The committee exchanges opinions about these priority issues with the Zero Accident Labor-Management Meeting, which consists of the Executive Officer responsible for SCQ, members on the Company-side consisting of representatives of in-house Companies, and labor union members representing sites under the jurisdiction of in-house Companies, and sets priority tasks for safety and health management. Specific measures for the Zero Occupational Accident Project such as these priority tasks are implemented after deliberations and approval at the Strategic Management Committee made up of Executive Officers. With the Mitsubishi Materials Safety, Environment & Quality Department playing a central role, the progress of these measures is reported at monthly meetings made up of Safety Coordinators appointed at in-house Company, and elsewhere, where we share information regarding progress and issues with safety and health measures at business sites under their management, including Group companies, and discuss solutions. The progress of each measure is also regularly reported to the Sustainable Management Office, of which the Presidents of each in-house Company are a part. In addition, the status of accidents that have occurred including occupational accidents, fires and explosions as well as the measures taken to deal with serious incidents are reported to the Strategic Management Committee and Board of Directors by the Executive Officer responsible for SCQ promotion, and are appropriately monitored.

Additionally, we have an integrated Group-wide promotion framework in place whereby matters that extend beyond the confines of individual Companies are reported and discussed at the above-mentioned Zero Occupational Accident Subcommittee, with improvements suitable for the conditions at each site made based on the PDCA cycle.

The occupational safety and health management systems are operated at individual business sites, and Safety and Health Committee meetings with members representing both the Company and the labor union are also held. The committee discusses measures related to worker hazards, investigates the causes of and works to prevent recurrences of serious matters including occupational accidents, and implements measures to prevent health issues and maintain the health of workers. In addition, Safety Managers, Safety Coordinators and Safety Instructors are assigned to individual business sites, where their role is to promote safety activities.

We hold regular Group-wide Safety Manager meetings and meetings for Safety Coordinators and Safety Instructors, where we exchange opinions on a wide range of occupational accident information and health and safety activities across the Group and the various business sectors in which it is involved, and strive to raise the level of health and safety.

Management Priorities

To expand the joint labor-management initiative to achieve zero occupational accidents, we have identified issues at the MMC Group identifies issues based on occupational accidents, etc. that occurred in the previous year, and after engaging in joint labor-management discussions on the particular items to be addressed to achieve solutions, designates management priorities. In 2023, we set out the following management priorities, and rolled out occupational safety and health management systems at each of our plants/factories accordingly.

Group-wide Priorities for Safety and Health Management (2023)

Thorough Efforts to Make Equipment Safe (engineering measures) through Risk Assessments (RA)

While the number of serious occupational accidents related to machines and electricity and those related to handled materials caused by equipment has been decreasing in the long term, there remains residual risk that we have yet to reduce, and accidents have occurred due to unrecognized hazard sources. In response, we decided to examine the appropriateness of risk assessments continuously from the fiscal year ended March 2021 onward, and implement a review. The actions we are taking are as follows.

- Identify new risks and lower the risk level

- Check for hazard sources and dangerous tasks that have yet to be identified

- Reassess risks which have been identified and take corrective actions against insufficient measures

- Promote the inherent safety of existing equipment

- Improve the skills of those conducting risk assessments, etc.

An analysis of the types of occupational accidents occurring at the MMC Group has revealed that many occupational accidents occur due to two main causes: flawed protective and safety measures and proximity to dangerous areas. As physical measures to address these issues, we have been reviewing structures and mechanisms from the perspectives of foolproof*¹ and failsafe*², and are employing thorough engineering-based action through risk assessments. Further, with respect to occupational accidents caused by “flawed operating methods” such as the use of inappropriate tools and jigs or incorrect operating procedures, we implement improvement measures that reflect the results of risk assessments, such as improvements including the verification of operating methods, and revised operating procedures that reflect hazard prediction.

Risk assessment is an effective means of discovering, eliminating or mitigating potential danger or harm attributable to operating practices and other work performed at a manufacturing site. At the MMC Group, we implement risk assessment activities from the perspective of workers on the production flour at each business site. We have trained risk assessment instructors at each business site to improve their ability to identify unsafe equipment states. We began offering training classes in October 2015, and as of March 2020, more than 520 people have taken the course (although classes could not be held from April 2020 onward due to the impact of COVID-19), contributing to enhancing and stimulating on-site activities. In addition, since August 2020, we have been conducting risk assessment classes by remote learning, led primarily by front line supervisors with the aim of raising the ability level of personnel who conduct risk assessments. 49 people received training in those classes in 2024, bringing the cumulative total to 634.

- *1 Foolproof: A function that prevents human error from resulting in an incident or occupational accident

- *2 Failsafe: A function ensuring that equipment will operate on the safe side in the event of mechanical malfunction, power outage or otherwise

Safety Record

State of Occurrence of Occupational Accidents

The number of employees involved in occupational accidents (injuries without lost time) in the Company and at 35 major Group companies stood at 90 in 2023. Sadly, 24 of these were accidents requiring employees to take leave. The number of accidents at the Company, on a non-consolidated basis, has been showing a downward trend for the past ten years, but it has leveled off in recent years. (The number of business sites increased by two as a result of the merger of the former Mitsubishi Shindoh Co., Ltd. in April 2020. In addition, after 2022 the cement business and aluminum business, in 2023 Yokkaichi Plant were shifted outside the Group due to business reorganization.)

We did not meet our goal of not causing any occupational accident resulting in four or more lost days for 365 days, producing a result of 82 days.

Change in the number of continuous days without an occupational accident resulting in four or more lost days

| 2020 | 2021 | 2022 | 2023 | |

|---|---|---|---|---|

| Number of days without an occupational accident | 91 | 41 | 135 | 82 |

In 2023, serious accidents involving workers being caught or entangled in equipment occurred. We re-confirmed equipment safety measures and reminded workers to thoroughly ensure that they “switch off the power whenever they need to reach into equipment with their hands” and “never extend their hands towards rotating objects” while working.

The accident frequency rate which evaluates the state of occurrence of occupational accidents taking place at the Company (LTIFR (Lost-Time Injury Frequency Rate): casualties per million actual hours worked (employees taking time off work)) was 0.85; a lower figure than the 2023 manufacturing business average of 1.29, and the non-ferrous metals industry average of 0.91 (Ministry of Health, Labour and Welfare (MHLW) statistical data). The accident frequency rate including accidents not requiring employees to take leave (TRIFR (Total Recordable Injury Frequency Rate): casualties per million actual hours worked including accidents not requiring employees to take leave) was 2.88.

In 2024, too, we worked thoroughly to further increase the safety of facilities through risk assessments, added further measures to prevent accidents, and made other efforts toward achieving our zero occupational accident target.

Safety Record Trend (Mitsubishi Materials)

- * The figures are based on calendar years. Occupational accidents frequency rate and incident rate do not include accidents during commuting or minor injuries. (After 2022, accidents from business sites related to the cement business and aluminum business, in 2023 Yokkaichi Plant were excluded.)

Number of employees injured

| 2020 | 2021 | 2022 | 2023 | ||

|---|---|---|---|---|---|

| MMC (Enrollment) | Fatal | 0 | 0 | 0 | 0 |

| Lost-time | 7 | 2 | 4 | 9 | |

| No lost-time | 17 | 18 | 22 | 21 | |

| MMC (Temporary workers, etc.) | Fatal | 0 | 0 | 0 | 0 |

| Lost-time | 0 | 1 | 1 | 1 | |

| No lost-time | 4 | 3 | 3 | 3 | |

| MMC (Subcontractor) | Fatal | 0 | 0 | 0 | 0 |

| Lost-time | 4 | 10 | 2 | 4 | |

| No lost-time | 19 | 17 | 6 | 7 | |

| Group companies (Incl. subcontractors) |

Fatal | 1 | 0 | 1 | 0 |

| Lost-time | 13 | 27 | 9 | 10 | |

| No lost-time | 83 | 84 | 41 | 35 | |

| Total | Fatal | 1 | 0 | 1 | 0 |

| Lost-time | 24 | 40 | 16 | 24 | |

| No lost-time | 123 | 122 | 72 | 66 | |

Injury Frequency Rate Trend

| 2020 | 2021 | 2022 | 2023 | ||

|---|---|---|---|---|---|

| Non-consolidated | LTIFR | 0.51 | 0.21 | 0.38 | ★0.85 |

| TRIFR | 2.03 | 1.68 | 2.30 | ★2.88 | |

| Subcontractors | LTIFR | 0.85 | 2.27 | 0.66 | ★0.98 |

| TRIFR | 4.92 | 6.12 | 2.62 | ★2.70 |

- * LTIFR (Lost-Time Injury Frequency Rate): casualties per million actual hours worked (number of victims of accidents requiring employees to take leave including deaths) = accident frequency rate, TRIFR (Total Recordable Injury Frequency Rate): casualties per million actual hours worked (number of victims of accidents requiring employees to take leave including deaths + number of victims of accidents not requiring employees to take leave)

State of Occurrence of Fires and Explosions

In 2023, there were 5 accidents (fires and explosions, etc.) at the Company. They include one case of fire, where it took a certain amount of time before the accident ended. However, all of the other 4 accidents were minor ones scoring 1 points or less under our internal accident evaluation standards, which are a measure of the magnitude of damage and impact. There was no explosion in 2023. There were zero (0)★ Tier 1 process safety events (PSEs) per million hours. The Company bases its definition of PSEs on the CCPS definition.*

In addition the total number of accidents has more than halved (15) from the number in 2022, and we will continue to pursue initiatives that focus on the prevention of similar accidents through the internal proliferation of accident data, among other measures.

- * Tabulated values are for the Company (non-consolidated) for the calendar year. Tier 1 PSE (Process Safety Events) are identified based on the "Process Safety Metrics: Guide for Selecting Leading and Lagging Metrics" Version 4.1 issued by CCPS.

Occurrence of Fires, Explosions and Other Accidents

| 2020 | 2021 | 2022 | 2023 | |||||

|---|---|---|---|---|---|---|---|---|

| Number of accidents | Score | Number of accidents | Score | Number of accidents | Score | Number of accidents | Score | |

| Fire | 6 | 5.1 | 10 | 18.3 | 13 | 35.1 | 3 | 3.9 |

| Explosion | 0 | 0.0 | 0 | 0.0 | 0 | 0.0 | 0 | 0.0 |

| Leakage, etc. | 1 | 0.3 | 6 | 1.8 | 2 | 0.6 | 2 | 0.6 |

| Total | 7 | 5.4 | 16 | 20.1 | 15 | 35.7 | 5 | 4.5 |

MMC-method Accident Assessment Criteria

| Severity level (points) | Assessment items | |||

|---|---|---|---|---|

| Human injury | Property damage | Impact of leakage/spill (Leakage of high-pressure gas, spill of hazardous material) |

Time it takes before a fire is extinguished (Duration of time between occurrence and extinguishment of a fire) |

|

| Ⅴ(27) | Multiple deaths | Property damage outside the premises | Impact on a wide area outside the premises, such as a river | 4 hours or longer |

| Ⅳ( 9) | One death or multiple lost days | Property damage to adjacent facilities on the premises | Impact on the area around the premises | 2 - 4 hours |

| Ⅲ( 3) | Lost time injury | Burnout or damage to the building with equipment as the fire source | Impact on adjacent facilities on the premises | 1 - 2 hours |

| Ⅱ( 1) | Injury without lost time | Burnout or damage of the equipment as the fire source, or minor damage to a part of the building with such equipment | Leakage/spill only inside the building with equipment as the fire source or inside protective facilities such as dikes | 30 minutes - 1 hour |

| Ⅰ(0.3) | Below Level II (Minor incidents) |

Below Level II (Minor damage to a part of the equipment as the fire source) |

Below Level II (Minor leakage/spill) |

Shorter than 30 minutes |

- * Set by referring to accident assessment criteria of the Japan Petroleum Industry Association and the severity indicators for fire and spill accidents at dangerous facilities, which were notified by the Fire and Disaster Management Agency.

- * To be evaluated based on the total number of points by summing the points for the intensity level of each evaluation item that applies.

- * The number of points shall be zero (0) if none of the intensity levels applies.

Enhancing Safety and Health Education

Occupational Safety and Health Education Center - “Midori-kan”

Occupational Safety and Health Education Center - “Midori-kan”

In the courtyard of the Midori-kan, a monument for safety and health surrounded by five materials symbolizing our business has been installed. The design employs a green cross representing safety.

In the courtyard of the Midori-kan, a monument for safety and health surrounded by five materials symbolizing our business has been installed. The design employs a green cross representing safety.

We thought that personal experiences of hazards are important to improve hazard awareness, so started running an Occupational Safety and Health Education Center - “Midori-kan” in March 2017. The center has 50 different hazard experience facilities inspired by the actual work environment and the dangers that hide in everyday tasks. It also regularly provides specialized education needed for work safety and health in dedicated classrooms, in addition to Hazard Sensitivity Education by expert instructors. In the fiscal year ended March 2024, roughly 340 employees underwent hazard experience education, and around 240 employees completed specialized education. Since its establishment, the center has provided hazard sensitivity training for about 4,600 Group employees, approximately 1,390 of whom have also completed specialized training courses as of March 2024.

Hazard Sensitivity Education Using Virtual Reality (VR)

We introduced VR as a part of hazard sensitivity training at our Occupational Safety and Health Education Center in May 2018. The system enables experiences that are difficult to simulate with regular equipment, providing participants with a 360º field of vision, better realism and immersion through haptic and other technologies. With the use of VR, participants can experience hazards through to the end (for example before, during and after falling), and is helpful for creating better hazard awareness. Because the devices are portable, we provide the training at each plant of the Group. In 2019, we introduced the second and third sets of devices and added five new hazard experience courses. We added another four courses in 2021. We began to lend them to Group companies as well, aiming to improve hazard awareness further.

VR hazard experience courses (Occupational Safety and Health Education Center)

Accidents involving contact with high temperatures

Accidents involving contact with high temperatures

(gas releases)

Accidents involving contact with high temperatures

Accidents involving contact with high temperatures

(steam explosions)

Accidents involving contact with forklifts

Accidents involving contact with forklifts

(driver moving forward)

Accidents involving contact with forklifts

Accidents involving contact with forklifts

(pedestrian moving backward)

Falling accidents

Falling accidents

(falling from crane)

Falling accidents

Falling accidents

(stepping through the floor)

Caught-between accidents

Caught-between accidents

(press)

Caught-in accidents

Caught-in accidents

(high-speed conveyor belt)

Caught-in accidents

Caught-in accidents

(slow-speed conveyor belt)

Electric shock accidents at power panels

Electric shock accidents at power panels

Tripping accidents caused by difference in height (falls)

Tripping accidents caused by difference in height (falls)

Accidents involving cutter incision wounds

Accidents involving cutter incision wounds

Falling accidents while descending stairs (fall)

Falling accidents while descending stairs (fall)

Stepladder fall accidents

Stepladder fall accidents

Flying object accident caused by failed crane operation

Flying object accident caused by failed crane operation

Grinder kickback accident

Grinder kickback accident

Fall accident while putting a cover on a trailer

Fall accident while putting a cover on a trailer

Pinched in a V-shaped belt

Pinched in a V-shaped belt

Strengthening Safety and Health Systems

Commendation System for Business Sites with Excellent Safety Records

To encourage improvements to safety management, we commend business sites that have made outstanding achievements in the Mitsubishi Materials Group. Business sites that are eligible for commendations are those of Mitsubishi Materials Corporation, consolidated subsidiaries in the manufacturing and construction industries in Japan, and some unconsolidated subsidiaries. Commendation criteria stipulate that the business site must achieve the required period (number of years) with no accidents requiring employees to take leave (a period during which no accidents requiring employees to take leave occur with regard to either company employees or contractors). Commendations are classified into the following three types.

(1) Safety distinction award (Business sites that achieve the number of years stipulated by commendation criteria)

(2) Safety excellence award (Business sites that achieve the number of years stipulated by commendation criteria x 2)

(3) Safety grand prize (Business sites that achieve the number of years stipulated by commendation criteria x3or more)

Since risks vary significantly between industries and business types, the number of years stipulated as commendation criteria is set for each business site based on the business type. Business sites are classified into the following groups.

- Group A (Criteria: every two years)

Business types: plant type (smelting), equipment-oriented industry (copper & copper alloy, etc.), construction industry - Group B (Criteria: every three years)

Business type: advanced materials & tools / processing and assembly type

October 2023 Commendations

| Advanced Products Company |

GOTOH MFG Co., Ltd. (No lost time injuries for 14 consecutive years) |

|---|

| Advanced Products Company | Mitsubishi Cable Industries, Ltd. Amagasaki Works (No lost time injuries for 6 consecutive years) |

|---|---|

| Metalworking Solutions Company |

Japan New Metals Co., Ltd. (No lost time injuries for 4 consecutive years) |

| No prize winning business sites |

April 2024 Commendations

| Metals Company | Materials Eco-Refining Co., Ltd. (No lost time injuries for 8 consecutive years) |

|---|---|

| Advanced Products Company |

Ceramics Plant (No lost time injuries for 18 consecutive years) |

| Management Strategy Dept. | Maintenance Techno Corporation (No lost time injuries for 10 consecutive years) |

| Advanced Products Company |

Tamagawa Seisakusho Co., Ltd. (No lost time injuries for 4 consecutive years) |

|---|

| No prize winning business sites |

- ※ Names of the commended organizations are as of the time of the commendation.

Safety and Health Instruction Utilizing Outside Consultants

The results of an analysis of past occupational accidents revealed issues in risk identification at MMC Group business sites. For this reason, we have been providing safety and health guidance through outside consultants. Risks that have previously not been recognized are identified from the viewpoint of an external expert and measures are taken to reduce such risks. This helps raise the on-site safety level and improves the hazard sensitivity of employees.

Promoting the Rollout of Information within the Group through Consolidation and Dissemination

The Safety, Environment & Quality Department has been running an internal portal website since February 2017 for the collection, dissemination, and viewing of information about safety, health, disaster prevention and the environment. Safety data and safety chronology to which there was previously only limited access along with occupational accident case studies, documents used for safety and health training and information concerning health and mental health have been classified, organized and published to the internal portal website. We produce videos depicting cases of typical occupational accidents that have occurred in the MMC Group, thus offering straightforward explanations of the conditions of an occupational accident, its cause, countermeasures taken and the lessons learned.

All past accidents in the Group have been entered into a database. That database has been available on the internal portal website mentioned above since June 2017. The database allows keyword and full-text searches and the creation of accident calendars, contributing to the preparation of safety education materials as well as measures against similar accidents. It is constructed so that all plants can obtain the necessary information swiftly and accurately, helping to bolster our safety foundation and foster a safety culture.

Disseminating Examples of Safety and Health Best Practices

Since 2014, we have been compiling a collection of safety and health best practices on a yearly basis, highlighting highly-effective initiatives implemented at each MMC Group business site to prevent occupational incidents. We are promoting the spread of best practices by presenting them during National Safety Week as a shared asset for improving the Group’s safety and health. We introduce individual case examples in the form of a “Safety Column” on the internal portal site, which serves to widely share knowledge related to safety and health along with information about related initiatives.

Assessing potential occupational and safety risks in new projects

We work to assess potential risks by investigating occupational and safety issues in the course of due diligence activities carried out with respect to potential acquisitions when we acquire companies or otherwise deal with new developments.

When high-risk events are discovered during due diligence activities, we require that the risks be eliminated within a certain period of time or stipulate how the risks are to be handled in the final contract. If the risks are not eliminated or no point of agreement can be found on how to handle them, we may forgo the contract.

Strengthening Response to SCQ Issues

- Prevention of Occupational Accidents

- Creating Mentally and Physically Pleasant Workplaces

- Prevention of Infectious Disease

- Reinforcing Compliance

- Enhancing Internal Control through Group Governance

- Group Tax Policy

- Enhancement of Corporate Governance

- Preventing Leakage of Harmful Substances Outside the Site and Eliminating Environmental Law Violations

- Elimination of Serious Quality Non-conformance