- Home

- Sustainability Report

- Mitsubishi Materials Group's Initiatives on Material Issues

- Reducing environmental impact

Strengthening Measures to Address Global Environmental Issues

Reducing Environmental Impact

Overall Environmental Impact

Among the following disclosure items, energy input includes data from sites belonging to the polycrystalline silicon business and salt manufacturing business.

Total Energy Input

Total energy input (non-consolidated) in the fiscal year ended March 2024 decreased by approximately 33% (3.3 petajoules: crude oil equivalent of 85 thousand kiloliters) in comparison with the fiscal year ended March 2023. This was partly due to a decrease in production at some plants, but also because of energy-saving activities such as the electrification of facilities and the introduction of high-efficiency equipment.

* 1PJ=1015J=1,000TJ

Raw Material Input

To contribute to the establishment of a material-cycle society, we are actively engaged in the recycling of waste and by-products, and promote the use of recycled raw materials such as waste and by-products.

Total raw material input for the Company for the fiscal year ended March 2024 was 1.32 million tons★, about the same as in the fiscal year ended March 2023. As a percentage of total raw material input, waste products and by-products accounted for 13.8%.

* Natural resources include limestone procured from Group mines up to the fiscal year ended 2022.

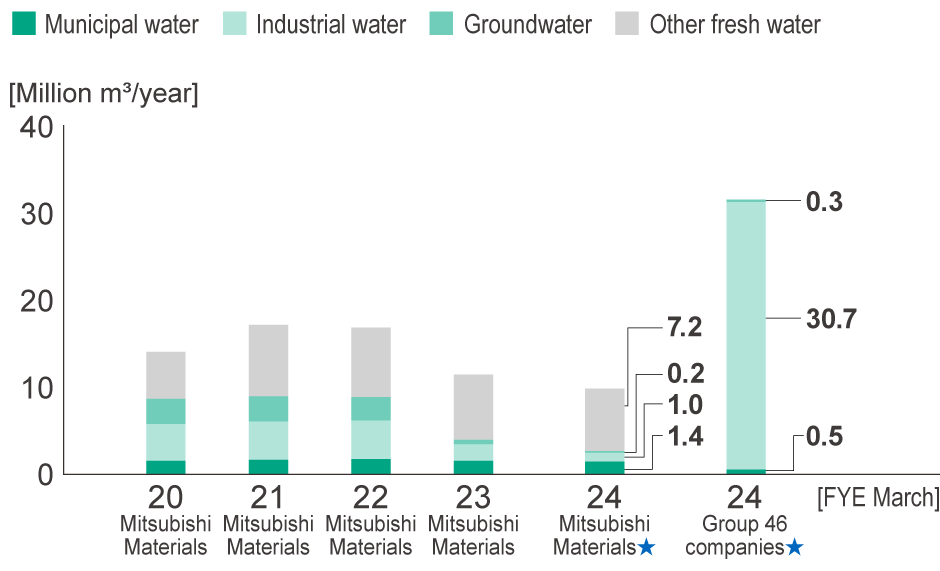

Water Intake

The vast majority of our water intake is seawater used as cooling water at our copper smelters and refineries.

The Company’s total water intake in the fiscal year ended March 2024 was 97.2 million tons★, about the same as in the fiscal year ended March 2023. 9.81 million m3★ (approximately 10%) of the total water intake was fresh water.

* Excluding fresh water used in hydroelectric power generation

* Excluding seawater used for cooling

Emissions into the Air and Bodies of Water

We monitor the amounts of sulfur oxides (SOx), nitrogen oxides (NOx) and dust contained in waste gases from facilities, as well as attributes such as BOD (biochemical oxygen demand), COD (chemical oxygen demand) and nitrogen content in wastewater.

Water Discharged

On a non-consolidated basis, the volume of water discharged (excluding water drained into the sea) by the Company in the fiscal year ended March 2024 was 9.40 million m3★, about the same as in the fiscal year ended March 2023. Water drained into the sea by the Company (non-consolidated) was 88.8 million m3, and the vast majority was seawater that had been used as cooling water.

* Excluding water drained into the sea

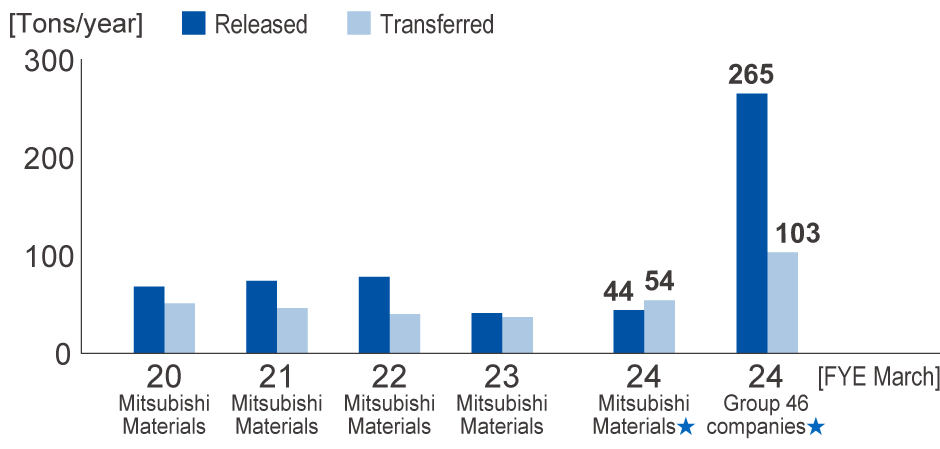

Chemicals Released or Transferred

The Company’s non-consolidated emissions in the fiscal year ended March 2024 increased by approximately 9% compared with the fiscal year ended March 2023 to 44 tons. The transferred amount increased by 23% compared with the fiscal year ended March 2023 to 53.6 tons★, reflecting the addition of one site which uses a large volume of chemicals to those subject to the monitoring of chemicals released or transferred, due to an amendment to the PRTR ordinance enacted in the fiscal year ended March 2023.

Volume of Industrial Waste

The volume of industrial waste from the Company (non-consolidated) in the fiscal year ended March 2024 declined by approximately 25% compared with the fiscal year ended March 2023 to 8.53 thousand tons★, because the polycrystalline silicon business was removed as a reporting entity from the fiscal year ended March 2023. The volume of waste sent to landfills by the Company (non-consolidated) was approximately 0.6 thousand tons, which was approximately 86% decreased from the fiscal year ended March 2023.

The total volume of waste for the Group as a whole, including Mitsubishi Materials, came to 44.2 thousand tons★, of which approximately 50% was recycled.

Preventing Air Pollution

The Group uses manufacturing processes that emit air pollutants such as dust and sulfur oxides (SOx) as a result of burning fuel, etc. In particular, emissions from our copper smelters and refineries account for the majority of those emissions. Each site is working to suppress emissions of air pollutants by stabilizing and increasing the efficiency of operations that generate emissions, and by installing advanced waste gas treatment equipment and maintaining appropriate performance.

Preventing Water Pollution

To prevent water pollution, at all of our sites we appropriately treat effluent and impose wastewater management standards that are even stricter than those required by law or municipal ordinance. In addition, to ensure we are ready to deal with leaks of chemical substances or oil spills, we take measures such as installing dikes and inspecting equipment on a daily basis. We also conduct regular training aimed at preventing the spread of substances in the event of a leak.

Chemical Substance Management

The Group’s manufacturing plants handle a diverse range of chemical substances. Each site is implementing measures to reduce environmental risks, such as reducing the use of hazardous chemical substances, preventing their leakage into the environment, and reducing emissions. Specific initiatives include the review of processes according to the characteristics of each chemical substance, the installation of new equipment, as well as the switch to less hazardous alternative substances.

Waste Management

To contribute to building a resource-recycling society, we take comprehensive measures to reduce waste discharge and recycle resources from discharged waste. We also engage in recycling operations.

Initiatives to Reduce the Release of and Recycle Industrial Waste, From Plastic Products

The Company falls under the category of large-volume waste generating business operator (a business operator generating at least 250 tons of industrial waste from plastic products a year) as defined by the Act on Promotion of Resource Circulation for Plastics. The Company has set targets concerning the reduction and recycling of industrial waste from plastic products as required by this designation, and is working to switch from heat recovery and landfill disposal to resource recycling.

Targets

- Switch to material recycling for the packaging plastics used for Company products

- Reduce the amount of plastic materials used in site business activities, consider the use of alternatives or switch to material recycling

The amount of industrial waste from plastic-using products, etc. in the fiscal year ended March 2024 was 1,032 tons. Of this amount, 714 tons was plastic that was not recycled (heat recovery, landfill, etc.), resulting in a 36% reduction in emissions and recycling compared to the fiscal year ended March 2022 (1,115 tons).

We ascertain the actual plastic waste generation of each Group company to confirm whether any fall under the category of large-volume waste generating business operators, and promote waste reduction and recycling activities.

Water-related Management

The vast majority (approx. 87%) of the water we consume at the Mitsubishi Materials Group is seawater used as cooling water. Consumption of fresh water (such as industrial water and groundwater) is comparatively low. However, because a shortage of fresh water may affect our business activities, securing the necessary quality and amount of water is essential for the business operation of the Group. One of the Group’s environmental policies is “Effectively Use and Conserve Water Resources,” and we are working to reduce the amount of water we use through its reuse, recycling and other efforts across every aspect of our business activities, including cooling water and cleaning water.

In addition, we have considered the seriousness of the water-related problems that have occurred frequently in recent years, such as typhoons and flooding, and the great impact of these problems. We manage the risks related to these problems accordingly. We implement measures for reducing water risks at individual facilities. To reduce our use of freshwater resources, we take action such as the effective use of seawater, water conservation through more efficient production processes, water recycling, and the thorough purification of wastewater. To secure water resources, we save water through measures including the recycling of water, the introduction of equipment with low water consumption, and the renovation of equipment to reduce water consumption. As measures against flooding, we take initiatives including the elevation of buildings, pumps, and electric equipment, the installation of drainage pumps, as well as the implementation of disaster drills assuming high water events. We also take measures to prevent abnormalities in the quality of the effluent from our facilities and to prevent water quality accidents. These measures include the management of effluent under our own standards that are stricter than laws and regulations, as well as the introduction of sensors that detect abnormal water quality and a system that stops water discharges automatically.

State of Water Risk Assessment Initiatives

To ascertain the state of water risks at the Group's manufacturing facilities (some of which include research institutes), we are utilizing the Aqueduct water risk assessment tool developed by the World Resources Institute (WRI) to conduct individual risk assessments for each facility, covering various water risks including those relating to securing water resources and those of incurring flood damage.

There were seven Group company locations rated as having high water stress, but sales related to these locations accounted for 7% of Group company sales. In the fiscal year ended March 2024, water withdrawal was 84,981 thousand m3 and water consumption was 1,285 thousand m3.

Additionally, in order to ensure that water risk assessments are in line with actual conditions at these facilities, we supplement the results of water risk assessments performed using Aqueduct by taking into account information including the history of any past water risks that have materialized at each facility (history of occurrences of flood, drought, and water supply quality deterioration, etc.) and water usage associated with business activities (amount of fresh water and groundwater used, emissions of pollutants contained in wastewater).

The results of these supplemented water risk assessments are used to produce visual representations of water risks for each facility, using radar charts displaying risk scores for each assessment item, and shared with each business location. Each business site registers items assessed as high risk as risk factors unique to that facility, and engages in risk management by formulating and implementing measures including the reduction of water risks.

Example Radar Chart Showing Water Risks for Each Facility

"Water quality risks" are assessed separately for both water supply and wastewater, from the viewpoints of impact on operations due to the deterioration of water supply quality and impact on the environment due to wastewater at business sites. "Regulatory and reputation risks" are also assessed for both water supply and wastewater, from the perspectives of toughness water supply and wastewater regulations and the reputation of the region.